- Central Air Conditioning

- Spilt units & Multi feed

- VRV VRV & VRF Systems

- Gas fired heating

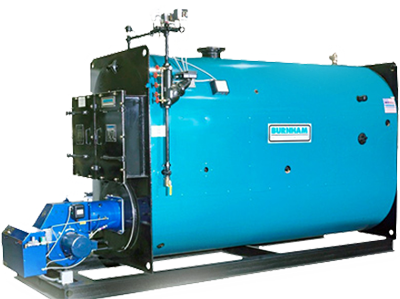

- Commercial Boilers

- Domestic heating boilers

- Air Halfling units

- Kitchen/ General extract

Central air conditioners circulate cool or warm air through a system of supply and return ducts. Supply ducts and feeds the building through openings in the walls, floors, or ceilings covered by grills, it carry cooled air from the air conditioner to the boiling weather it is home or offices. This air becomes changes in temperature as it circulates through the building; then it flows back to the central air conditioner through return ducts, this system contains list of items that should be tested, serviced and checked regularly to avoid system breakdown.

- System Control Gear

- Compressor(s)

- Refrigerant circuits

- Refrigerant filters

- High/Low pressure switch

- Condensers fan motors

- Condenser coil

- Condenser coil Sensors

- Water flow valve/ switch (chillers)

- Water circulation pumps (chillers)

- Remote thermostat

All the above parts need to be assessed, checked, function tested and Serviced on one by one bases to ensure correct system operation, Our engineers are qualified and highly experienced in diagnosing these parts failures and can carry all types of service and repairs on these systems, We only makes use of original replacement parts and accessories. In fact, our warehouse is stocked with authentic and factory spare parts to ensure that we can deliver prompt service or repair whatever the make and model of your system may be.

Our engineers only use top-of-the-line test instruments and tools when providing repairs or service. This is to ensure that the job gets done in an efficient manner and that your system are guaranteed to be safe from further damage or future breakdown.

A split air-conditioning system, is an outdoor unit contains the condenser, condenser fan(s) and compressor, and an indoor unit(s) contains the evaporator(s). In many split-system air conditioners, this indoor unit also contains a heater or the indoor part of a heat pump. The air conditioner's evaporator is usually installed either hidden in the ceiling void or on show as in cassette systems or wall mounted this will depend on the building structure and availability of space to house the system, this system contains list of items that should be tested, serviced and checked regularly to avoid system breakdown.

- System Control Gear

- Compressor(s)

- Refrigerant circuits

- Refrigerant filters

- High/Low pressure switch

- Condensers fan motors

- Condenser coil

- Condenser coil Sensors

- Water flow valve/ switch (chillers)

- Water circulation pumps (chillers)

- Remote thermostat

All the above parts need to be assessed, checked, function tested and Serviced on one by one bases to ensure correct system operation, Our engineers are qualified and highly experienced in diagnosing these parts failures and can carry all types of service and repairs on these systems, We only makes use of original replacement parts and accessories. In fact, our warehouse is stocked with authentic and factory spare parts to ensure that we can deliver prompt service or repair whatever the make and model of your system may be.

Our engineers only use top-of-the-line test instruments and tools when providing repairs or service. This is to ensure that the job gets done in an efficient manner and that your system are guaranteed to be safe from further damage or future breakdown.

VRV system (Variable Refrigerant Volume) and VRF system (Variable Refrigerant Flow) are both referring to a type of air conditioning system which is based on Inverter technology compressors, the first VRV is a trade mark of Daiken as they invented the technology while VRF is the more common term usually used for these types of systems, VRF can easily be related to as the “Rolls Royce” of Air Conditioning Systems. It’s a very sophisticated technological air conditioning system, based on several principles:

- Refrigerant only – where refrigerant is the only coolant material in the system

- Inverter compressors that allow lowering power consumption with partial cooling/heating loads.

- Several air handlers (indoor units) on the same refrigerant loop / circuit

- Ability of modular expansion (especially applicable for large projects, that can grow in stages)

The operation logic of the VRF is fully built-in inside the system and is proprietary for each VRF manufacturer. The system gets inputs from the user (e.g. desired comfort temperature) and from the surroundings (outside ambient temperature), and according to that data it implements its logic in order to get to the desired comfort conditions, utilizing optimal power consumptions. The ability to adjust itself to the outdoor conditions is one of the main factors that makes VRF systems so efficient, compared to the traditional water cooled systems, based on chillers and fan coils.

All parts of the above systems need to be assessed, checked, function tested and Serviced on one by one bases to ensure correct system operation, Our engineers are qualified and highly experienced in diagnosing these parts failures and can carry all types of service and repairs on these systems, We only makes use of original replacement parts and accessories. In fact, our warehouse is stocked with authentic and factory spare parts to ensure that we can deliver prompt service or repair whatever the make and model of your system may be.

Our engineers only use top-of-the-line test instruments and tools when providing repairs or service. This is to ensure that the job gets done in an efficient manner and that your system are guaranteed to be safe from further damage or future breakdown.

Direct gas-fired air-handling units (AHUs) have provided efficient, reliable makeup air for many high-exhaust/infiltration industrial applications and facilities, such as paint booths, distribution centers, warehouses, and factories, The heating coil is fabricated by expanding copper tube to aluminum collar spaced fins at a suitable pitch to meet key design performance parameters. These fins, which are staggered in the direction of the airflow, are mechanically bonded to deliver excellent heat transfer characteristics.

- General microwave oven system problems

- Dead controller

- Control panel or touch pad issues

- Abnormal humming or buzzing sounds

- Microwave oven generator problems

- Microwave oven timer problems

- Microwave oven fuse problems

- Turntable not working

- Microwave heating issues

- Microwave oven damaged interior

- Sensor problems

All the above parts need to be assessed, checked, function tested and Serviced on one by one bases to ensure correct system operation, Our engineers are qualified and highly experienced in diagnosing these parts failures and can carry all types of service and repairs on these systems, We only makes use of original replacement parts and accessories. In fact, our warehouse is stocked with authentic and factory spare parts to ensure that we can deliver prompt service or repair whatever the make and model of your system may be.

Our engineers only use top-of-the-line test instruments and tools when providing repairs or service. This is to ensure that the job gets done in an efficient manner and that your system are guaranteed to be safe from further damage or future breakdown.

Throughout Europe, the most popular way to provide central heating and hot water for all types of commercial buildings, such as schools, hotels, offices, hospitals and even large apartment blocks, is by using a boiler specially designed for commercial situations. Commercial boilers can be run on natural gas, liquid petroleum gas or oil. Increasingly, they are being combined with low carbon technologies, such as solar panels and heat pumps.

- Traditionally, floor standing boilers are used. However, for smaller commercial buildings, space saving wall hung boilers may be suitable

- It is very common to use more than one boiler in multiple or cascade format in a plant room. This system means that the increased heating and hot water needs of a large building can be met, and it is also capable of providing a standby facility

- As well as providing the heating, a boiler can be used to provide the building's hot water requirements using an indirect hot water storage tank or calorifier, a device that heats the water by circulating it over heating coils. Alternatively where hot water demand is high, for example a hotel, a separate direct water heater system may be used and the boilers used for heating only

- Commercial boilers can be either conventional or condensing

All the above parts need to be assessed, checked, function tested and Serviced on one by one bases to ensure correct system operation, Our engineers are qualified and highly experienced in diagnosing these parts failures and can carry all types of service and repairs on these systems, We only makes use of original replacement parts and accessories. In fact, our warehouse is stocked with authentic and factory spare parts to ensure that we can deliver prompt service or repair whatever the make and model of your system may be.

Our engineers only use top-of-the-line test instruments and tools when providing repairs or service. This is to ensure that the job gets done in an efficient manner and that your system are guaranteed to be safe from further damage or future breakdown.

“The appliances of yesterday were simply made of better materials and were built to last!” If you’ve heard your grandma repeat this mantra, you aren’t alone. That is the common thought of many people today. However, the reality is there is much more diversity in the appliances that are available now. Some of the big names in appliances like Viking, Kenmore, LG, Frigidaire, Maytag, and Decor are as good or better than the appliances of the old days. They come with more features, and better energy-savings so that you can save on your energy bills.

- Range hood ducting

- Range hood filters

- Aluminum grease filters

- Carbon odour filters exhaust filters

- Filter Retaining Clips

- Fluorescent Tubes

All the above parts need to be assessed, checked, function tested and Serviced on one by one bases to ensure correct system operation, Our engineers are qualified and highly experienced in diagnosing these parts failures and can carry all types of service and repairs on these systems, We only makes use of original replacement parts and accessories. In fact, our warehouse is stocked with authentic and factory spare parts to ensure that we can deliver prompt service or repair whatever the make and model of your system may be.

Our engineers only use top-of-the-line test instruments and tools when providing repairs or service. This is to ensure that the job gets done in an efficient manner and that your system are guaranteed to be safe from further damage or future breakdown.

Air-handling units (AHUs) have provided efficient, reliable circulation of air for many buildings and industrial applications and facilities, such as distribution centers, warehouses, and factories, this type of units are equipped with air circulation fan, air filtration unit, hearing and cooling coils to change the temperature of the treated air according to the desired settings, it may also be designed to makeup fresh air in accordance to your ventilation system design. The heating/cooling coil are mounted in the return air stream and usually fabricated by expanding copper tube to aluminum collar spaced fins at a suitable pitch to meet key design performance parameters. These fins, which are staggered in the direction of the airflow, This type of kit require regular maintenance and checks on it’s components to ensure correct operation .

- Affordable repair services

- Highly skilled repair experts

- Quality and all-original parts

- On-time and speedy service

- Expert diagnosis and No hidden charges

- Cleaning and maintenance services

All the above parts need to be assessed, checked, function tested and Serviced on one by one bases to ensure correct system operation, Our engineers are qualified and highly experienced in diagnosing these parts failures and can carry all types of service and repairs on these systems, We only makes use of original replacement parts and accessories. In fact, our warehouse is stocked with authentic and factory spare parts to ensure that we can deliver prompt service or repair whatever the make and model of your system may be.

Our engineers only use top-of-the-line test instruments and tools when providing repairs or service. This is to ensure that the job gets done in an efficient manner and that your system are guaranteed to be safe from further damage or future breakdown.

The extract system and range hood is one of the most crucial appliances installed in a commercial kitchen space as it extracts unwanted smoke, grease, heat, and moisture out of the kitchen working space. In short, to achieve proper ventilation and ensure clean indoor air, the installation of an extract system is a must. A benefit of a extract system’s primary function is that it increases the level of comfort during the preparation and cooking of meals. Imagine how frustrating and annoying it is for anyone to cook in a kitchen covered in smoke, heat, and grease! It is not the most pleasant feeling that one would like to endure while cook in, you see. Lastly, kitchen extract systems ensure that other kitchen appliances, fridges, freezers, countertops, walls, and flooring are kept clean and germ-free. Without a properly installed kitchen extract, your kitchen will be a gooey, sticky mess! Thick films of grease and dirt layered on top of each other are hard to remove from surfaces. The ventilation power of kitchen extract systems efficiently traps smoke and grease before it can even have the chance to land on the items in and around your kitchen, below are some of the major components of such extract systems.

- Extract fan

- Extract fan motor

- Drive belts and polies

- Air-flow switches

- extract filters/ canopy filters

- control gear( inverters and contactors)

Every part of this system need to be assessed, checked, function tested and Serviced on one by one bases to ensure correct system operation, Our engineers are qualified and highly experienced in diagnosing these parts failures and can carry all types of service and repairs on these systems, We only makes use of original replacement parts and accessories. In fact, our warehouse is stocked with authentic and factory spare parts to ensure that we can deliver prompt service or repair whatever the make and model of your system may be.

Our engineers only use top-of-the-line test instruments and tools when providing repairs or service. This is to ensure that the job gets done in an efficient manner and that your system are guaranteed to be safe from further damage or future breakdown.